Fluid Bed Dryer

Fluid Bed Dryer Features:

- Very versatile process equipment.

- Fully automatic operation based on PLC control.

- Minimum handling and more hygienic.

- Top mounted telescopic cylinder for auto bag shaking.

- Clamp type bottom mesh for container.

- Capacity available from 2.5 kgs. To 500 kgs.

- MOC SS 304 / 316 / 316L.

- CGMP with documentation.

Product Description

Gentleman Pharmed is the world’s leading Manufacturer, Supplier, and Exporter for Fluid Bed Dryer ( Bed Dryer, FBD Dryer Equipment )

Fluid Bed Dryer (FBD):

A Fluid Bed Dryer (FBD) is a kind of equipment that’s mainly used in the pharmaceutical industries to overcome the moisture content of pharmaceutical granules and powder.

Fluid Bed Dryer (FBD) Working Principle:

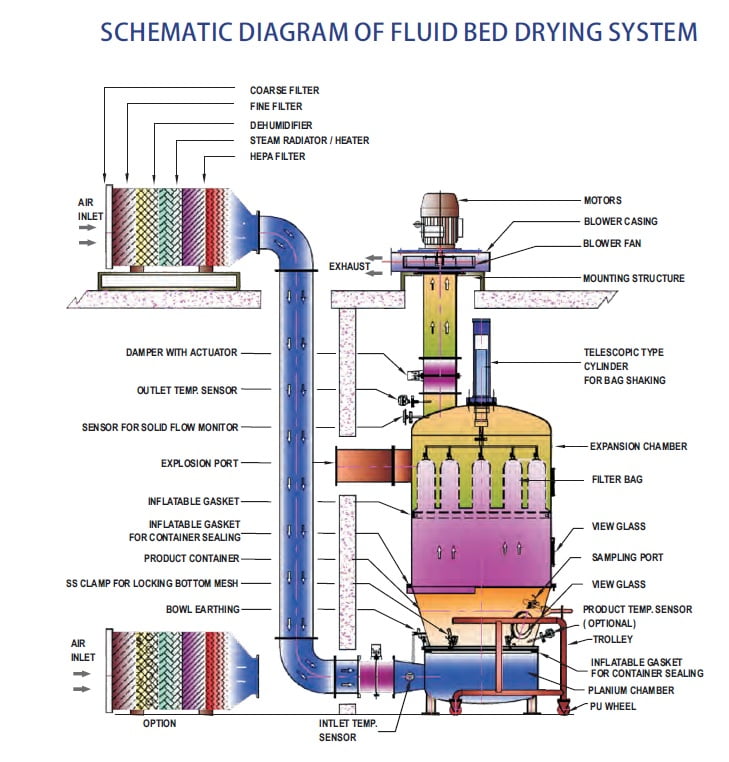

The Bed Dryer(FBD) design works on a principle of fluidization of the feed materials. A Batch of product loaded into the material bowl is seated in the chamber & heated filtered air is drawn through the product.

By this, the entire surface of an individual particle is surrounded by the hot air thus achieving a homogeneous distribution of temperature and as a result of this, a rapid and careful drying down to the smallest- residual moisture.

Escape of material from the granulation chamber is prevented by exhaust filters, which are periodically agitated or purged to reintroduce the collected material into the fluidized bed. The product can be cooled and the material container exchanged for the next batch. The quantity of air is regulated by means of an outlet air damper

only.